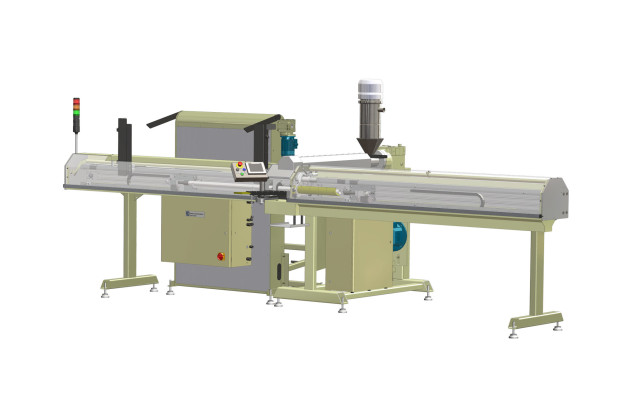

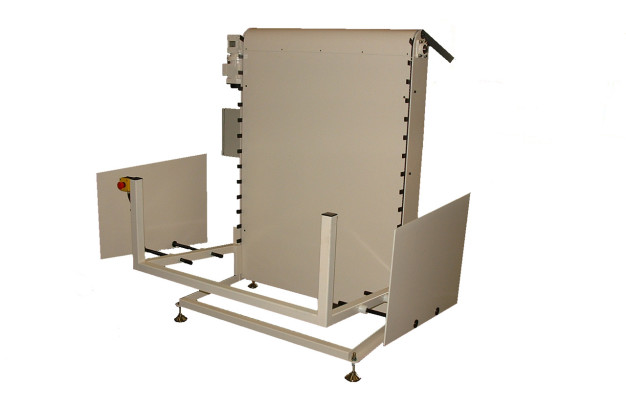

Helix+ (Plus) Thermo-Bonder Winding Machine

Modernise and Maximise Your Production

The Jackson Helix+ Thermo-Bonder is an advanced, very high output thermofusion paint roller winding machine that winds and bonds pile fabric on to pre-cut core tubes.

This machine is the latest in our line-up, the greater extruder capacity of the Helix+ is aimed specifically at high volume producers. The enhanced output facilitates high speed production of rollers greater than 1.5" (38mm). Dependent upon the finished product specification, the Helix+ can produce up to 10 wound tubes per minute of 1.75" (44.5mm) and above.

Paired with one of our HSF machines this machine has the capacity to produce 5400 high quality, finished paint rollers per hour.

The plastic melt delivers consistent strong adhesion and a high quality, cost effective end product. The benefits of a clean, controlled and accurate process speak for themselves

For machine sales, information and pricing:

+44 1953 60 67 63 | info@edwardjacksonltd.com

For spare parts and technical queries

+44 1953 60 67 63 | sales@edwardjacksonltd.com

Key Features

Product Specification

Videos

Spare Parts

Standard Product Warranty

Contact us about the Helix+ (Plus) Thermo Bonder

Contact us about the Helix+ (Plus) Thermo Bonder

For machine sales, information and pricing, please contact:

+44 1953 60 67 63

info@edwardjacksonltd.com

For spare parts and technical queries, please contact:

+44 1953 60 67 63

sales@edwardjacksonltd.com

Alternatively, you can submit an enquiry using our online enquiry form and we will get back to you: