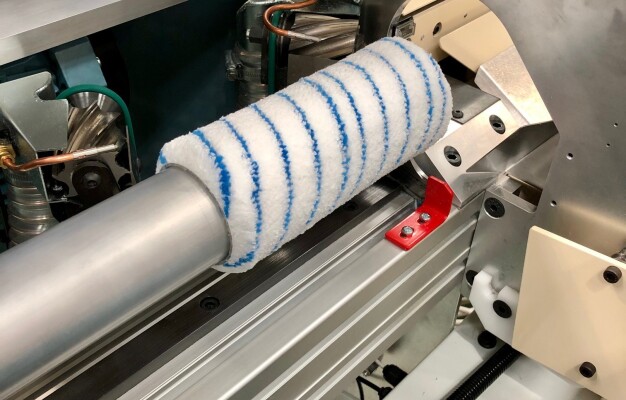

R3 Paint Roller Finishing Machine

Designed For Flexibility

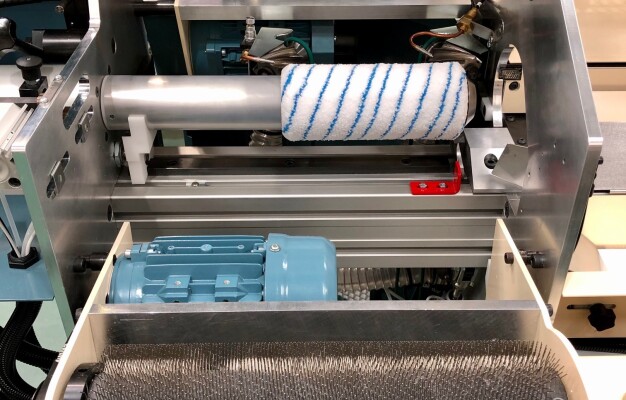

The R3 cutting and finishing machine is the successor to the popular R2. Quality roller finish and flexibility of use are still core to the design, the design revision has just enhanced those properties.

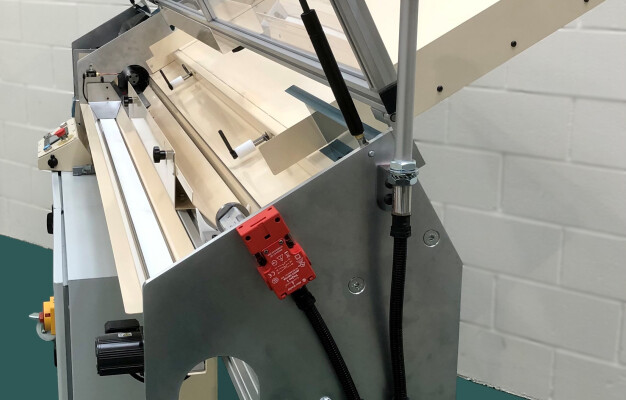

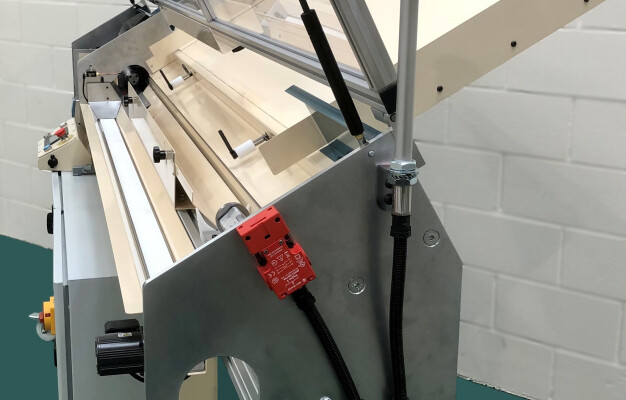

Automatic beveller positioning allows multiple finished roller lengths to be cut from one wound tube with no operator intervention.

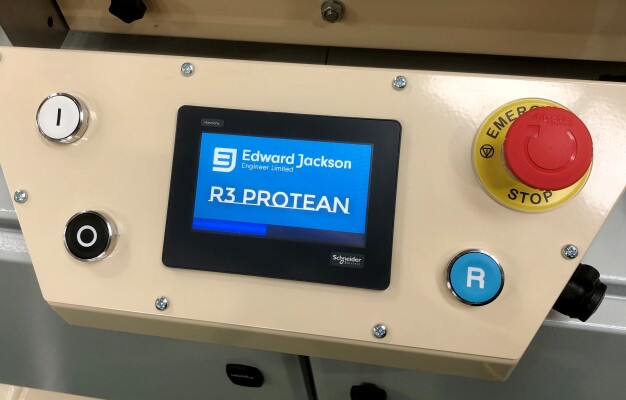

All new Schneider HMI control using the latest generation hardware and software keeps this machine at the forefront of automation.

Put simply, we believe the R3 to be the answer to producing a varied product portfolio, consistently, effectively and efficiently on a single machine. Our design is based around producing your high quality products and meeting your customers varied needs.

For machine sales, information and pricing:

+44 1953 60 67 63 | info@edwardjacksonltd.com

For spare parts and technical queries

+44 1953 60 67 63 | sales@edwardjacksonltd.com

Key Features

Product Specification

Videos

Spare Parts

Standard Product Warranty

Contact Us

Contact Us

For machine sales, information and pricing, please contact:

+44 1953 60 67 63

info@edwardjacksonltd.com

For spare parts and technical queries, please contact:

+44 1953 60 67 63

sales@edwardjacksonltd.com

Alternatively, you can submit an enquiry using our online enquiry form and we will get back to you: