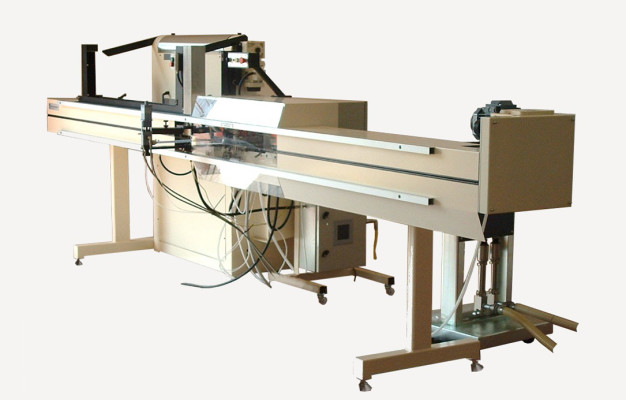

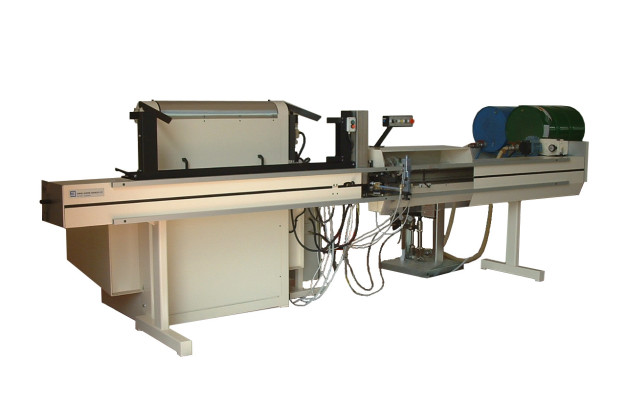

W3 Continuous Roller Winder

Consistent, Reliable Quality

The W3 roller-winder is a tried and tested workhorse of the Edward Jackson range. With a robust design and proven track record, this is an ideal choice for producers who make high quality products in low to medium volumes. The effective, but simple control system is an advantage for producers who operate in a less connected facility or region.

The precise epoxy mixing and application gives this machine the flexibility to process Polypropylene (PP), PVC and Phenolic core tubes. The surface treatment unit achieves excellent adhesion to smooth PP and PVC tubes, saving the expense of a pre-treatment 'roughing' process.

The automatic tube loader and continuous winding process allow a single operator to produce up to 5 core tubes per minute.

For machine sales, information and pricing:

+44 1953 60 67 63 | info@edwardjacksonltd.com

For spare parts and technical queries

+44 1953 60 67 63 | sales@edwardjacksonltd.com

Key Features

Product Specification

Videos

Spare Parts

Standard Product Warranty

Contact Us

Contact Us

For machine sales, information and pricing, please contact:

+44 1953 60 67 63

info@edwardjacksonltd.com

For spare parts and technical queries, please contact:

+44 1953 60 67 63

sales@edwardjacksonltd.com

Alternatively, you can submit an enquiry using our online enquiry form and we will get back to you: